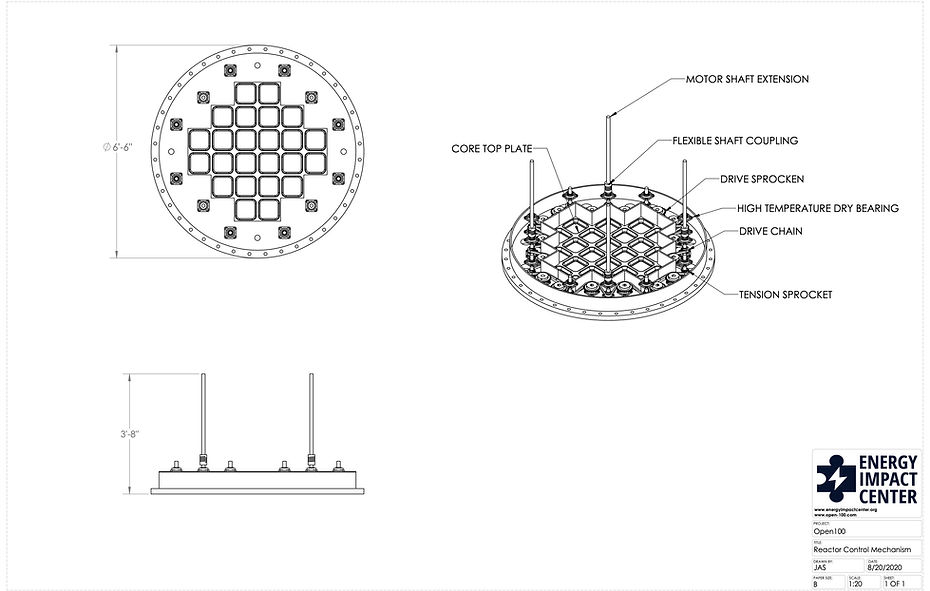

Control

OPEN100 supports two different mechanical control strategies. Control drums are rotary units around the periphery of the core while control rods are linear units inserted axially into the core. Both control drums and rods are comprised of a neutron absorbing material, such as boron carbide, such to absorb neutrons and control reactivity. Conventionally, in utility scale PWRs, control rods are utilized. However, in smaller cores where neutron leakage rates are much higher, reactivity control by method of leakage control can be effective. One method of accomplishing leakage control is via control drums around the periphery of the core. The leakage rate must be sufficiently high to generate acceptable control drum effectiveness to adequately control reactor reactivity. This leakage rate is determined by core geometry, materials, operating conditions and core enrichment/poison patterns. Proper configuration of these parameters is being closely studied on the OPEN100 reactor core and optimism for this control mechanism exists. However, if this arrangement proves to be impractical, conventional control rods will be utilized. Motivation for the use of control drums centers around supply chain and economics. Control rod drives are expensive and nuclear specific. Rotational drives and equipment are extremely common and it is believed that control drums would have significant economic and supply chain advantages to control rods. If control rods must be used, the number of drives will be minimized.

Vendor Options

Detailed Design Specifications